Tension fluctuation: ≤5%

Cleaning method: Ultrasound

Sizing unit: 0.3m

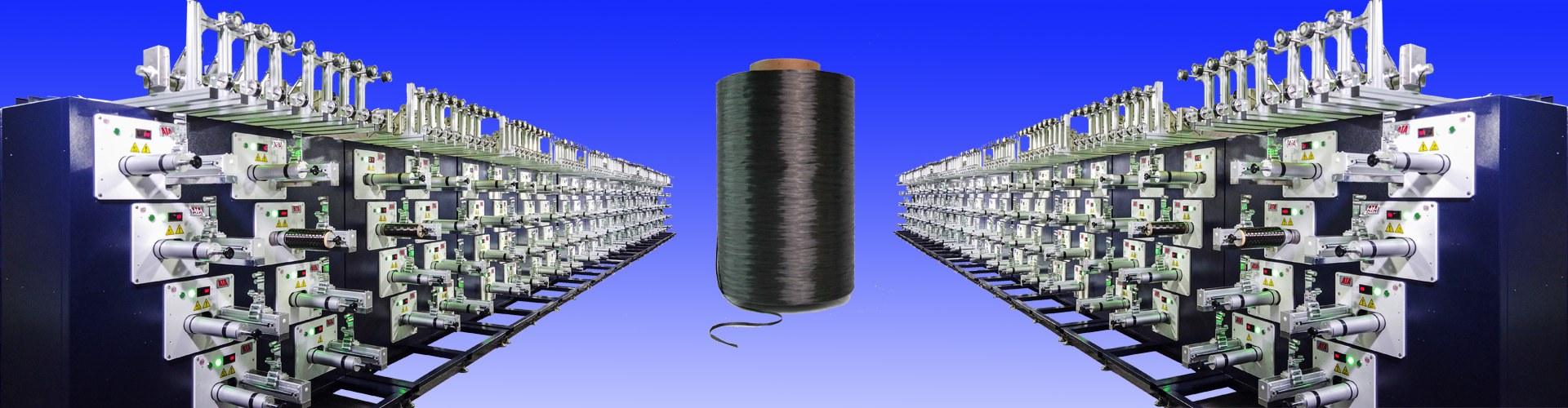

Multi-Functional Fiber Sizing Line is used for the desizing and sizing for carbon fiber, glass fiber, aramid fiber, basalt fiber , carbon nanotube fibers and other special fibers. It is the ideal experiment & research equipment for enterprise unit, the scientific research institute, the university research organization.

Unwind unit technical features:

1. Motor driven unwinding, tension independent setting

2. Tension closed-loop control, tension fluctuation less than or equal to 5%

3. The fiber unwind speed is automatically synchronized with the drawing speed to keep the yarn tension stable

4. No twisting, no damage on fiber, sound-light alarm on failures.

Cleaning and desizing unit technical features:

1. Ultrasonic cleaning machine can be removed, convenient cleaning

2. Ultrasonic vibration frequency and time can be set

3. Quick cleaning, high efficiency, reduce the labor intensity of cleaning

Sizing unit technical features:

1. Used for covering the surface of the tow with polymer slurry to protect the tow and improve the composite properties of the tow;

2. Sizing method is dip method;

3. Sizing length is 0.3m, sizing time is adjusted by speed.

4. Sizing tank can be dismantled for easy cleaning;

5. The extrusion pressure of the rubber roller can be adjusted, with the function of tow spreading, and the sizing is more even;

6. Excess sizing extruded by rubber pressing roller flows back into the sizing tank along the tow to avoid environmental pollution.

Drying unit technical features:

1. Used for drying the fibers after cleaning and sizing;

2. Hot air goes from the bottom to up, hot and humid air exhausted from the top outlet of the drying oven;

3. Drying on both sides of the oven, the hot air direction is parallel to the running direction of the tow, so as to reduce the vibration of the tow and the generation of fuzz;

4. Two ovens were used to dry the desized tow and the sized tow separately.

Drive unit technical features:

1. The driving system provides power for the running of the tow and regulates the running speed of the whole line;

2. The speed of the whole line is regulated by frequency converter;

3. After 3 rollers drive processing, ensure the stable tension before the tow enters into the winder.

Winder unit technical features:

1. The winder is used for winding the fibers. The tow is wound to the tube through the reciprocating screw motion guided by the yarn guide piece, which can effectively reduce the tension instability caused by the included Angle of the yarn guide wheel and the intersection angle of the winding spindle , and improve the quality of the winding spindle;

2. The tension of wire winding can be adjusted by setting the handle. The tension range is 100-1000g;

3. The winder follows the running speed of the whole line and maintains the set tension unchanged.

Electrical control system features;

1. Winding, unwinding, drawing and two drying ovens are independently controlled by switches;

2. Sound and light alarm alarm for the whole line failure;

3. The frequency converter panel is installed outside the electric cabinet to facilitate the adjustment of the linear speed;

4. All devices of the whole line are under centralized and unified control.

- The whole line is driven by the 3 rollers drive unit, can set the tension for tow unwinding and rewinding separately.

- When the tow is running, it will automatically follow the set tension, and the speed will automatically synchronize with the driving speed of 3 rollers. No matter how fast or slow the driving speed changes, the running tension of the tow will not be affected

- The fiber is unwound by each guide roller and enters the tension control system, and then transported forward by the transition roller;

- Uniform fiber feeding tension, small fiber damage, high degree of automation, no turning and twisting of fiber.

HOME

HOME